Fork Wear Test Calipers

Examining forks for wear and damage is key to keeping your equipment running smoothly. Fork Calipers from Arrow can easily test your forks for wear and keep you in compliance with OSHA and ANSI standards.

OSHA/ANSI/ITSDF B56.1-2009 standards state that forks must be inspected for wear and forks with 10% or more wear to the blades must be removed from service.

Measurement Instructions:

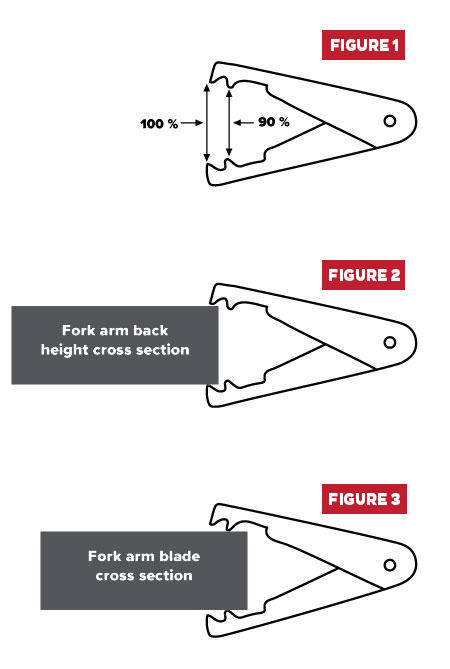

The outside jaws are used to set the calipers (Fig. 1). The inside jaws measure 10% less than the outside jaws.

- To inspect a fork, set the outside jaws by lightly closing the calipers against the back height (shank) of the fork (Fig. 2).

NOTE: distortion may occur if force is used in closing the calipers. Hold the calipers square at 90◦ for accurate measuring.

- When the calipers are set to the back height thickness, move them to the blade of the fork. If the inside jaws (Fig. 3) slide over the blade at any point between the heel and the beginning of the taper, the fork should be removed from service.

NOTE: Full tapered forks should be measured within 2 inches of the heel.

Fork Wear Indicator

Join in the future of forklift forks. The new standard in identifying fork wear is here. The fork wear indicator makes it easy to quickly determine fork wear, plan for future replacement, and prevent fork related accidents.

Our patented Fork Wear Indicator is innovating how operators and safety managers identify forks that are approaching unsafe wear levels. This solution is set to be the new industry standard in forklift fork manufacturing, and is currently only available on select Arrow ITA forks.

The easy to read wear indication sticker and stamp save time by eliminating sole reliance on traditional fork calipers. Inspectors now have a clean, clear, and readily available visual reference of fork wear and safety of the system.